http://www.stategeologists.org/temp/AASG%20Hydraulic%20Fracturing%20statement.pdf

August 12, 2012 | Association of American State Geologists“After decades of hydraulic fracturing-related activity there is little evidence if any that hydraulic fracturing itself has contaminated fresh groundwater. No occurrences are known where hydraulic fracturing fluids have moved upward from the zone of fracturing of a horizontal well into the fresh drinking water.” Quoted from the Association of American State Geologists statement. |

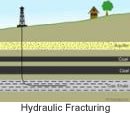

Hydraulic fracturing as applied in the oil and gas industry (commonly referred to as "fracking," "fracing," or "hydrofracking") is

the process of pumping a mixture of water, sand or similar material, and chemical additives, under high pressure, to create small

interconnecting fractures to increase permeability in targeted subsurface rock formations. Oil and gas companies perform

hydraulic fracturing after a well is drilled, cased and cemented, to increase the well’s productivity. Sand is used to prop open the

fractures, and chemical additives reduce friction, control bacteria, decrease corrosion, and serve other purposes. More than 50

percent of the natural gas, and a growing percentage of the oil, produced in the U.S. comes from hydraulically fractured

reservoirs. The following statement describes hydraulic fracturing in the oil and gas industry, discusses environmental concerns

about the practice and associated activity, and expresses the position of the Association of American State Geologists (AASG).

For an oil or gas well to be productive, hydrocarbons must flow through the rocks in which they are contained (the reservoir) into

the well and to the surface. Much of the oil and gas resource in the U.S. resides in "tight" rock formations, rocks so impermeable

that they do not allow oil and gas to flow easily through the rock to the wellbore. Reservoir rocks are fractured to enhance their

permeability and enable oil and natural gas to flow. Hydraulic fracturing is employed on both traditional vertical wells and on

horizontal wells, which are increasingly common. Most of these wells would not flow at rates that would make the drilling of the

well worthwhile without hydraulic fracturing. The combination of horizontal wells and hydraulic fracturing has led to increasing both

oil and natural gas production and the addition of large new reserves in the United States after years of decline.

Hydraulic fracturing was first used in the oil and gas industry in the U.S. in 1947. Since then, more than one million oil and gas

wells have been hydraulically fractured in the U.S., and hydraulic fracturing has become a common well-stimulation technique.

The application of hydraulic fracturing to horizontally drilled wells uses higher volumes of fluids than more traditional applications.

Today’s accumulated geological and engineering knowledge and improved technology are used to protect public health and the

environment while producing larger volumes of oil and gas. Modern wellbore casing and cementing are designed to isolate

freshwater aquifers from hydraulically fractured oil and gas reservoirs, which are generally thousands of feet below the aquifers.

Casing and cementing are required and regulated by state regulatory agencies and have performed as intended in the oil and

natural gas wells already drilled and currently operating in the U.S.

Environmental impacts are a concern for any activity on or below the land’s surface, including drilling and hydraulically fracturing

an oil or gas well. Constant vigilance is imperative to insure the quality of air, land, and water. Environmental issues raised in

association with hydraulic fracturing and other drilling and production operations include the potential for contamination of fresh

groundwater, water consumption, earthquakes triggered by injecting fluids, venting or flaring methane, and the disposal of fluids.

When they occur, most of these problems are not related to hydraulic fracturing, but to the drilling, casing and cementing of the

well, or disposal of fluids.

After decades of hydraulic fracturing-related activity there is little evidence if any that hydraulic fracturing itself has contaminated

fresh groundwater. No occurrences are known where hydraulic fracturing fluids have moved upward from the zone of fracturing of

a horizontal well into the fresh drinking water. In a single case currently under investigation, contamination may have occurred

when a vertical well was hydraulically fractured in a zone just a few hundred feet below the base of the freshwater. In most cases,

however, freshwater aquifers are near the surface, and are thousands of feet above deeply buried oil- or gas-bearing formations.

Under these geologic conditions, it is highly unlikely that a connection would develop between a hydraulically fractured oil or gas

reservoir and a freshwater aquifer. To further minimize the chance of such a connection, it is important to locate and plug any

abandoned wells that could provide a conduit between reservoir rocks and shallower freshwater aquifers, although no cases are

known where this has led to groundwater contamination from hydraulic fracturing fluids. Contamination has occurred, however,

from spills or mishandling of hydraulic fracturing fluids on the surface. Sound professional and regulatory practices therefore

should be diligently followed when handling fluids on the surface to minimize or eliminate this source of contamination.

Known instances of methane migration associated with well drilling are unrelated to hydraulic fracturing and could occur while

drilling any kind of well. All wells should be carefully cemented and tested properly to avoid methane migration. In some areas,

methane occurs in water wells because there is a natural source of methane within or just beneath the aquifer and in these cases

methane was present in water wells long before drilling or the use of hydraulic fracturing. It is important for oil and gas regulatory

agencies to determine if methane in freshwater wells has increased following drilling activities. This can only be done if baseline

water quality testing is carried out before oil and gas drilling. Also, enhanced practices and regulations may be required to

minimize release of methane, a greenhouse gas, to the atmosphere.

Introduction

The Association of American State Geologists (AASG) represents the State Geologists of the

50 United States and Puerto Rico. Founded in 1908, AASG seeks to advance the science

and practical application of geology and related earth sciences in the United States and its

territories, commonwealths, and possessions.

www.stategeologists.org

AASG statement

State geological surveys are important sources of information and expertise related to subsurface geology, water resources, and

energy. AASG members regularly monitor and discuss issues related to hydraulic fracturing. Several state surveys have been

engaged in investigations of potential freshwater contamination that may have been caused by recent hydraulic fracturing-related

activities; others are undertaking research on, and providing information about, hydraulic fracturing. The following points constitute

AASG’s position on hydraulic fracturing:

• AASG advocates that comprehensive public information based on sound science and open processes be utilized when

formulating energy and environmental policy. We encourage a balanced, independent, fact-based analysis of controversies

regarding natural resource development.

• AASG supports and encourages the disclosure of hydraulic fracturing fluids and chemical additives on FracFocus, the

hydraulic fracturing chemical registry website, developed by the Interstate Oil and Gas Compact Commission (IOGCC) and the

Groundwater Protection Council (GWPC).

• AASG advocates for better understanding and scientific documentation of our subsurface geology and aquifers, which will

result in improved geologic models to help all parties avoid problems that might occur during drilling and hydraulic fracturing

activities of oil or gas reservoirs, especially in new fields. This will allow safer and enhanced production of oil and gas.

• AASG is committed to protecting the nation’s public safety and the natural environment, including groundwater and

surface-water resources. AASG supports the wise and prudent production of oil and gas resources to help fulfill the nation’s

energy needs.

• AASG recognizes the economic and social importance, and the abundance, of oil and gas resources that only can be

recovered if reservoir rocks are hydraulically fractured.

• AASG maintains that state oil and gas regulatory agencies are best equipped, through statutory authority, expertise, and

experience, to ensure that hydraulic fracturing and all other operations associated with oil and natural gas development

proceed in a manner that protects the natural environment, including public safety as well as groundwater and surface-water

resources.

• AASG recognizes that the environmental record of hydraulic fracturing activities over the past 60 years has been

overwhelmingly positive. AASG also maintains that operators who do not follow regulatory requirements should be

appropriately sanctioned and, where appropriate, barred from conducting further oil and gas operations.

• AASG notes that geologic data generally show a significant vertical separation between most oil and natural gas reservoirs

targeted for hydraulic fracturing and the shallower freshwater aquifers. In areas where targets of hydraulic fracturing are

comparatively close to freshwater aquifers, thorough geologic characterization of the area is warranted and even greater

caution should be exercised by operators and regulatory agencies.

• AASG recognizes the fast pace of recent drilling for oil and natural gas and the associated hydraulic fracturing activities. AASG

suggests that caution and careful attention to community relations be exercised by operators, contractors, and regulators in the

design, review, approval, documentation, implementation, and verification of plans for the drilling, completion, stimulation and

production of oil and gas wells.

• AASG encourages continuing work to acquire and maintain local pre-drilling water quality assessment and ongoing information

on groundwater quality, and recommends that casing and cementing operations in hydraulically fractured wells be carefully

documented by operators, contractors, and regulators.

Water used for hydraulic fracturing is generally obtained from nearby water wells, lakes, streams and rivers. Although a

substantial amount of water is used in hydraulic fracturing, this represents a one-time use, and the amount is considerably less

than the volumes required in other common ongoing uses, such as agriculture, municipal supplies, and industrial processes. Oil

and gas operators must follow state laws in the acquisition and use of water and make sure that they do not negatively impact

local (individual, city, or county) water supplies. The industry is working to reduce their freshwater needs, including recycling the

water they use in hydraulic fracturing operations.

Much of the water used in hydraulic fracturing flows from the well along with gas, oil, and saline water during normal production

operations. That "wastewater," or “flow-back water," must be recycled or disposed of properly. Disposal is generally through deep

wells drilled specifically for that purpose. In some locations, injecting returned water into deep wells has triggered small earthquakes

(generally less than Magnitude 3.0), a phenomenon called triggered seismicity or induced seismicity. Proper well siting

away from faults and using managed injection rates and pressures can minimize or eliminate triggered seismicity.

With new technologies, exploration has expanded into areas and communities that have seen little oil and gas drilling, or have

not seen it recently. That has created a variety of new issues--some positive, some negative. Caution, good judgment, and sound

regulatory practices must be exercised in areas where less information is available about the subsurface geology.

Co-Chairs, Energy Committee Co-Chairs, Environmental Policy Committee

Scott W. Tinker Nick Tew Karl Muessig David K. Norman

scott.tinker@beg.utexas.edu ntew@gsa.state.al.us karl.muessig@dep.state.nj.us dave.norman@dnr.wa.gov

Texas State Geologist Alabama State Geologist New Jersey Geological Survey WA Div. of Geology and Earth Resources

No comments:

Post a Comment